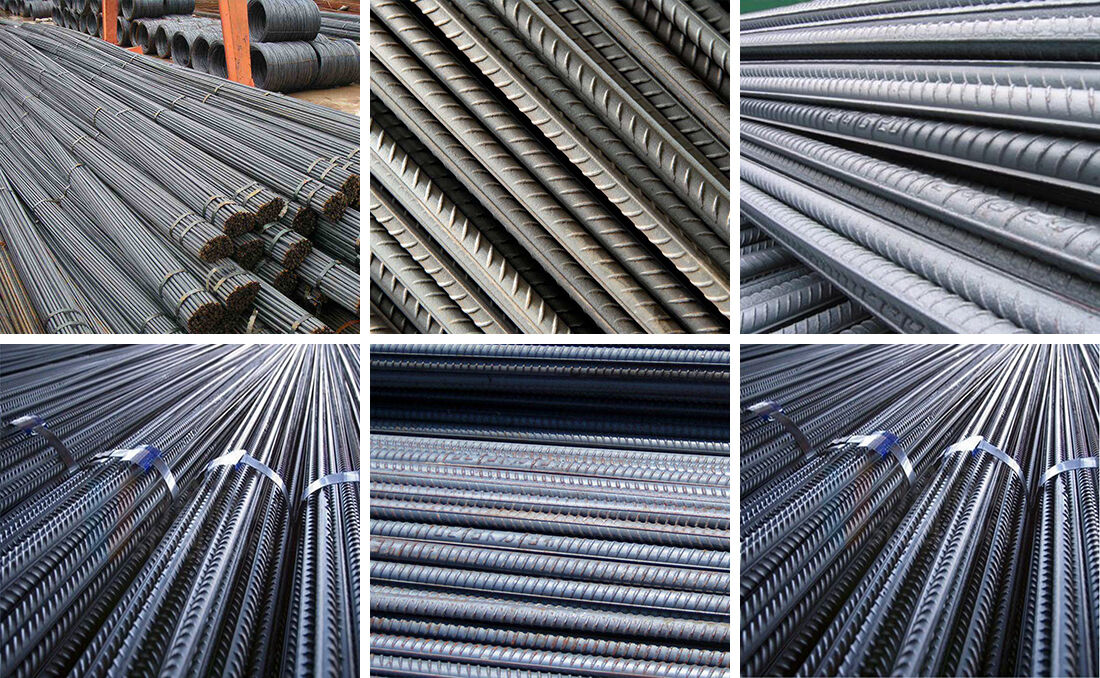

Rebar is a common name for hot-rolled ribbed steel bars. The grade of ordinary hot-rolled steel bar consists of HRB and the minimum yield point of the grade. H, R, and B are the initials of three words: Hotrolled, Ribbed, and Bars. Reinforcing bars are ribbed steel bars on the surface, also known as ribbed steel bars. Usually, there are two longitudinal bars and transverse bars evenly distributed along the length. The shapes of transverse ribs are spiral, herringbone and crescent. It is expressed in millimeters of nominal diameter.

| Product Name | Deformed Steel Rebars,Rebar |

| Material | HPB300,HRB335,HRB400e,HRB500e,B500b, etc. |

| Size | 6mm,8mm,10mm, 12mm, 13mm, 14mm, 16mm, 20mm, 22mm, 25mm, 30mm, 32mm, 40mm,50mm |

| Length | 5m-14m,5.8m,6m,10m-12m,12m or as customer's actual reques |

| Standard | BS4449-2005,GB1449.2-2007,JIS G3112-2004, ASTM A615-A615M-04a, |

| Grade | Grade 40, Grade 60, Grade 80 |

| Section Shape | Spiral Shap,Herringbone Shap,Crescent Shap |

| Technique | Steel Rebar Iron Rod |

| Packing | Bundle, or with all kinds of colors PVC or as your requirements |

| Surface Treatment | 1. Galvanized2. PVC,Black and color painting3. Transparent oil,anti-rust oil4. According to clients requirement |

| Origin | China |

| Certificates | ISO9001-2008 |

| Delivery Time | Usually within 3 days after receipt of advance payment |

| Mechnical Properties of Steel Rebars |

| Standard | Grade | Nominal Diameter mm | Yield Strength MPa (min.) | Tensile Strength MPa (min.) | Tensile to Yield Ratio (min.) | Elongation in 200mm (min.) | Elongation (A5) (min.) | Agt % (min.) |

|

| SASO ASTM A615M | 280(40) | 12 | 280 | 420 | N/A | 12 | N/A | N/A |

|

| 280(40) | 14 - 18 | 280 | 420 | N/A | 12 | N/A | N/A |

|

| 420(60) | 12 - 20 | 420 | 620 | N/A | 9 | N/A | N/A |

|

| 420(60) | 25 | 420 | 620 | N/A | 8 | N/A | N/A |

|

| 420(60) | 32 - 40 | 420 | 620 | N/A | 7 | N/A | N/A |

|

| 520(75) | 12 - 25 | 520 | 690 | N/A | 7 | N/A | N/A |

|

| 520(75) | 32 - 40 | 520 | 690 | N/A | 6 | N/A | N/A |

|

| SASO ASTM A706M | 420(60) | 12 - 20 | 420-540 | 550 | 1.25 | 14 | N/A | N/A |

|

| 420(60) | 25 - 36 | 420-540 | 550 | 1.25 | 12 | N/A | N/A |

|

| 420(60) | 40 | 420-540 | 550 | 1.25 | 10 | N/A | N/A |

|

| BS 4449 | 460 B | 12 - 40 | 460 | N/A | 1.08 | N/A | 14 | 5 |

|

| BS 4449 | B500B | 12 - 32 | 500 | N/A | 1.08 | N/A | N/A | 5 |

|

| GCC Standard GS06/IS0 6935-2 | B400BR | 12 - 40 | 400 | N/A | 1.08 | N/A | 14 | 5 |

|

| B400BWR | 12 - 40 | 400 | N/A | 1.08 | N/A | 14 | 5 |

|

| B500BR | 12 - 32 | 500 | N/A | 1.08 | N/A | 14 | 5 |

|

| B500BWR | 12 - 32 | 500 | N/A | 1.08 | N/A | 14 | 5 |

|

| Chemical composition of Steel Rebars |

|

|

|

|

|

|

|

|

|

| Standard | Grade | Chemical composition % (maximum) |

|

|

|

|

|

|

|

|

| C | Si | Mn | S | P | N | Cu | C.E.V |

| SASO ASTM A615M | 280/420/520 (40/60/75) | ... | ... | ... | ... | 0.06 | ... | ... | ... |

| SASO ASTM A706M | 420(60) | 0.3 | 0.50 | 1.5 | 0.045 | 0.035 | ... | ... | 0.55 |

| BS 4449 | 460 B | 0.25 | ... | ... | 0.05 | 0.05 | 0.012 | ... | 0.51 |

| BS 4449 | B500B | 0.22 | ... | ... | 0.05 | 0.05 | ... | 0.80 | 0.50 |

| GCC Standard GS06/IS0 6935-2 | B400BR / B500BR | ... | ... | ... | 0.06 | 0.06 | ... | ... | ... |

| B400BWR / B500BWR | 0.22 | 0.60 | 1.60 | 0.05 | 0.05 | 0.012 | ... | 0.50 |

| Linear Mass and Number of Bars In Bundles |

| Diameter (mm) | Nominal linear mass kg/m | Tolerance in linear mass (maximum) | Tolerance in linear mass (maximum) | Tolerance in linear mass (maximum) | Number of 12 mlong bars in a bundle of nominal weight of 2 tons. |

|

| ASTM A615 | BS 4449:2005 | GCC Standard GS06/ISO 6935-2/2007 |

|

| 12 | 0.888 | –6% | ±4.5% | ±6% | 188 |

| 14 | 1.210 | –6% | ±4.5% | ±5% | 138 |

| 16 | 1.580 | –6% | ±4.5% | ±5% | 105 |

| 18 | 2.000 | –6% | ±4.5% | ±5% | 84 |

| 20 | 2.470 | –6% | ±4.5% | ±5% | 68 |

| 22 | 2.980 | –6% | ±4.5% | ±4% | 56 |

| 25 | 3.850 | –6% | ±4.5% | ±4% | 44 |

| 28 | 4.830 | –6% | ±4.5% | ±4% | 34 |

| 32 | 6.310 | –6% | ±4.5% | ±4% | 26 |

| 36 | 7.990 | –6% | ±4.5% | ±4% | 21 |

| 40 | 9.870 | –6% | ±4.5% | ±4% | 17 |